Machinery & Production Lines

Machinery & Production Lines

Drip Chamber and Spike Assembly Machine (Type 2) for Infusion Sets – Shunjin Medical

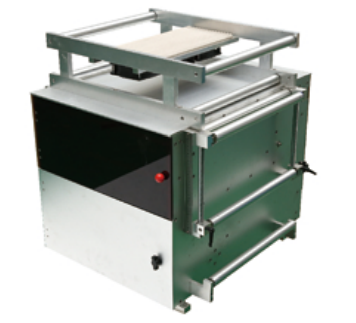

Drip Chamber and Spike Assembly Machine (Type 2)

The Drip Chamber and Spike Assembly Machine (Type 2) from Shunjin Medical is built for high-efficiency assembly of key IV infusion set components including the drip chamber, filter, spike and cap. It is designed for medical disposables factories that require consistent, repeatable assembly quality while increasing throughput and reducing reliance on manual labor.

The machine is engineered with a clear automated sequence: parts are fed and positioned, pressed and assembled under controlled motion, and the output is monitored by sensors to support stable quality. This approach reduces human handling and helps manufacturers minimize defects, improve batch consistency and streamline downstream processes such as tubing assembly, packaging and sterilization workflows.

With an output capacity of 5,500–6,000 pcs per hour, the machine supports high-volume operation and is suitable for manufacturers serving hospitals and medical distribution supply chains. The utility requirements are compatible with typical factory setups: three-phase AC 220V, 50/60 Hz electrical supply and standard compressed-air infrastructure. The design also targets simple operation with minimal training, enabling a single operator to manage routine production tasks and monitoring.

Automation and component reliability are supported by industrial brands commonly used in production automation. PLC control and touch-screen HMI simplify operation and troubleshooting, while pneumatic and sensing components are selected to support stable actuation and part detection in continuous operation.

Medical relevance: the drip chamber is used in IV administration sets to allow air to separate from the fluid path and to help observe and calculate gravity-based drip rates. The spike is the sterile piercing part used to access IV fluid bags or bottles. High-quality assembly of these parts supports safer IV set performance and easier quality assurance for medical-device manufacturers.

- 5,500–6,000 pcs/h output

- Assembles drip chamber + filter + spike + cap

- PLC control and touch-screen operation

- Designed for IV infusion set production lines

Technical Specifications

| SKU | SJ-DRIP-SPIKE-ASM-002 |

|---|---|

| Assembly speed | 5, 500–6, 000 pcs/h |

| Assembly parts | Drip chamber; Filter; Spike; Cap |

| Machine weight | 1800 kg |

| Dimension (L×W×H) | 3000 × 3500 × 2000 mm |

| Air consumption | 0.04 m³/h |

| Air pressure | 0.6–1 MPa |

| Power | 5 kW |

| Voltage | Three-phase AC 220V, 50/60 Hz |

| Operators needed | 1 person |

| PLC brand | Keyence |

| Touch panel (HMI) | Flexem |

| Servo system | Mitsubishi |

| Pneumatic cylinder | SMC |

| Solenoid valve | Niscon |

| Category | Machinery & Production Lines |

| Tags | Infusion Sets |

Ready to Place Your Order?

Get a customized quote for your business needs. Our team is ready to assist you with bulk orders, technical specifications, and delivery options.

Reviews

There are no reviews yet.