Machinery & Production Lines

Machinery & Production Lines

Drip Chamber and Spike Assembly Machine (Type 1) for Infusion Sets – Shunjin Medical

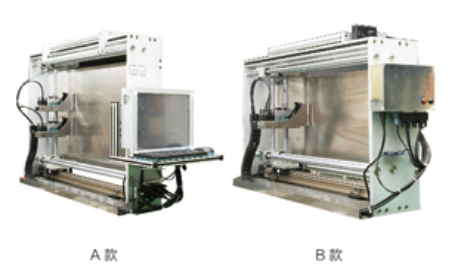

Drip Chamber and Spike Assembly Machine (Type 1)

This fully automatic Drip Chamber and Spike Assembly Machine from Shunjin Medical is designed to assemble core components used in IV infusion sets: drip chamber, filter, air vent, filtering membrane, spike and cap. It helps medical disposables manufacturers shift critical assembly steps from manual processes to an automated, repeatable workflow, supporting stable output and consistent quality on medium to high-volume production lines.

In practical production, the machine follows a sequenced assembly route: components are fed into position, the membrane and vent parts are checked and pressed, the drip chamber and filter are assembled, adhesive steps are applied where required, then the spike and chamber are connected, capped, and the finished sub-assemblies are unloaded. Integrated inspection and controlled reject behavior helps prevent defective items from passing downstream, improving yield and reducing rework.

Output performance is rated at 5,000–5,500 pcs per hour with a compact operator requirement of 1–2 persons per machine. The machine is engineered for continuous factory operation with utilities matching typical medical manufacturing installations, including three‑phase AC 220V (50/60 Hz) power and standard compressed air supply. A rigid frame and industrial layout support stability during high-speed operation.

For automation and user experience, the machine integrates PLC-based control and a touch-panel HMI to simplify operation, parameter setting and alarm troubleshooting. Specified components across electrical, pneumatic and sensing systems are chosen from widely used industrial brands, supporting long-term reliability and maintenance planning for international customers.

Medical relevance: drip chambers help manage air separation and monitoring in gravity-driven IV administration, and the spike is the sterile piercing component for IV fluid containers. Consistent assembly of these parts supports safe, stable infusion set performance and easier downstream integration into full IV set lines and packing systems.

- 5,000–5,500 pcs/h output

- Assembles drip chamber + filter + air vent + membrane + spike + cap

- PLC control with touch-panel operation

- Ready for integration into full infusion set manufacturing lines

Technical Specifications

| SKU | SJ-DRIP-SPIKE-ASM-001 |

|---|---|

| Assembly speed | 5, 000–5, 500 pcs/h |

| Assembly parts | Drip chamber; Filter; Air vent; Filtering membrane; Spike; Cap |

| Machine weight | 2200 kg |

| Dimension (L×W×H) | 3800 × 3500 × 2000 mm |

| Air consumption | 0.06 m³/h |

| Air pressure | 0.6–1 MPa |

| Power | 8 kW |

| Voltage | Three-phase AC 220V, 50/60 Hz |

| Operators needed | 1–2 persons |

| PLC brand | Keyence |

| Touch panel (HMI) | Flexem |

| Optical fiber system | Panasonic |

| Pneumatic components | AirTAC (pneumatics); SMC (air cylinders) |

| Frequency converter | Mitsubishi |

| Servo system | Mitsubishi |

| Category | Machinery & Production Lines |

| Tags | Infusion Sets |

Ready to Place Your Order?

Get a customized quote for your business needs. Our team is ready to assist you with bulk orders, technical specifications, and delivery options.

Reviews

There are no reviews yet.