Machinery & Production Lines

Machinery & Production Lines

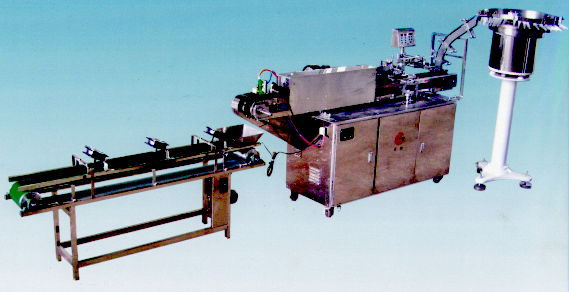

Latex Connector Assembly Machine for Infusion Sets – Shunjin Medical

Latex Connector Assembly Machine for IV Infusion Sets

The Latex Connector Assembly Machine from Shunjin Medical is an automatic production solution designed to assemble the latex tube together with a luer connector and a hypodermic needle, creating a key sub‑assembly used in IV infusion set manufacturing. By moving this sensitive step from manual work to automated handling, manufacturers can improve repeatability, stabilize throughput and reduce handling-related defects in clean production environments.

The process is engineered around reliable component feeding and controlled assembly steps. Parts are guided into position through stable feeding mechanisms, then joined through a controlled bonding/assembly sequence, followed by checking and controlled unloading. This structured workflow helps maintain consistent positioning and connection integrity, which is critical for preventing leakage and ensuring stable connections within infusion sets. The result is a smoother upstream process for factories that later integrate drip chambers, roller clamps and tubing into complete infusion sets.

Performance is optimized for industrial output. The machine is rated for 6,000–6,500 pieces per hour and is designed for continuous operation with low manpower requirements (1–2 operators). Utility requirements are aligned with typical medical-device factory infrastructure: single‑phase AC 220V, 50/60 Hz power and standard compressed air within a common industrial pressure range.

For control and reliability, the system uses a PLC-based architecture and an HMI touch panel interface, allowing technicians to monitor status, adjust parameters and respond to alarms quickly. Major electrical and pneumatic components are specified as recognizable industrial brands to support maintenance planning and spare‑parts availability across markets.

Typical applications: infusion set sub‑assembly production, medical disposables factories scaling from semi‑manual to automated assembly, and production lines where stable connector/needle-to-tube joining is required as a prerequisite for downstream packaging and sterilization workflows.

- High-speed production: up to 6,500 pcs/hour

- Assembles latex tube + luer connector + hypodermic needle

- PLC control with touch-screen operation

- Designed for integration into complete IV infusion set lines

Technical Specifications

| SKU | SJ-LATEX-CONNECTOR-ASM-001 |

|---|---|

| Assembly speed | 6, 000–6, 500 pcs/h |

| Assembly parts | Latex tube; Luer connector; Hypodermic needle |

| Machine weight | 800 kg |

| Dimension (L×W×H) | 2300 × 2200 × 2100 mm |

| Air consumption | 0.05 m³/h |

| Air pressure | 0.6–1 MPa |

| Power | 5 kW |

| Voltage | Single phase AC 220V, 50/60 Hz |

| Operators needed | 1–2 persons |

| PLC brand | Keyence |

| Touch panel (HMI) | Flexem |

| Optical fiber system | Panasonic |

| Pneumatic components | AirTAC (pneumatics); SMC (air cylinders) |

| Frequency converter | Mitsubishi |

| Solenoid valve | Niscon |

| Relay | Dinkle |

| Magnetic sensor | ALIF |

| Category | Machinery & Production Lines |

| Tags | Infusion Sets |

Ready to Place Your Order?

Get a customized quote for your business needs. Our team is ready to assist you with bulk orders, technical specifications, and delivery options.

المراجعات

لا توجد مراجعات بعد.