Machinery & Production Lines

Machinery & Production Lines

Spike Assembly Machine for Infusion Sets – Shunjin Medical

Spike Assembly Machine for IV Infusion Sets

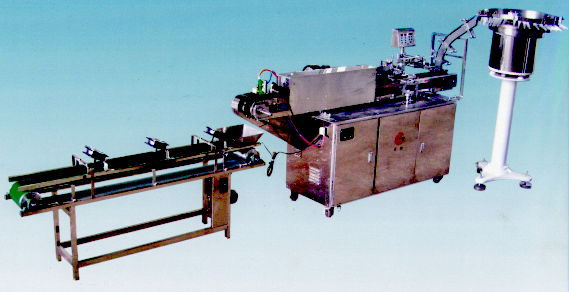

The Spike Assembly Machine from Shunjin Medical is an automatic assembly solution designed to produce complete spike units used in IV infusion sets. It assembles the spike body together with the protective spike cap and functional elements such as the air vent and filter membrane, creating a vented spike sub-assembly ready for integration with drip chambers and IV tubing sections.

In IV administration sets, the spike is the sterile piercing component used to access IV fluid bags or bottles. Where vented designs are used, the air vent and membrane help maintain sterile air exchange and reduce particulate ingress. Consistent assembly quality is therefore critical, because spike performance directly affects fluid access, leakage prevention and downstream IV set reliability.

This machine is engineered for high-volume output at approximately 5,500–6,000 pcs per hour. Automated feeding and assembly steps reduce manual handling, helping manufacturers improve repeatability and limit operator variability. The machine is designed for clean manufacturing layouts and controlled environments typical in medical disposables factories, supporting stable operation and easier quality management.

Operation is simplified through PLC-based control combined with a touch-panel HMI, allowing operators to monitor counts, adjust parameters and respond to alarms quickly. Inline part detection and positioning support stable assembly and reduce scrap rates. The configuration specifies widely used industrial brands across electric, pneumatic and sensing components to support reliability and maintenance planning for international customers.

From a compliance perspective, automated spike assembly supports better process repeatability and traceability than purely manual methods. When paired with downstream functional tests and in-process checks, consistent spike assembly contributes to more predictable performance in final IV sets. Manufacturers can also integrate this station into broader automation cells that include drip chamber assembly, roller clamp assembly and tube/connector assembly, building a modular production flow that scales with capacity needs.

Typical applications: vented spike sub-assembly production for IV infusion sets, high-volume infusion set factories, and integrated production lines where spikes are later assembled with drip chambers, roller clamps, latex connectors and needles before final packing and sterilization.

- 5,500–6,000 pcs/h output

- Assembles spike + cap + air vent + filter membrane

- PLC control with touch-panel operation

- Designed for integration into full IV set lines

Technical Specifications

| SKU | SJ-SPIKE-ASM-001 |

|---|---|

| Assembly speed | 5, 500–6, 000 pcs/h |

| Assembly parts | Spike; Spike cap; Air vent; Filter membrane |

| Machine weight | 1000 kg |

| Dimension (L×W×H) | 1800 × 3000 × 2000 mm |

| Air consumption | 0.05 m³/h |

| Air pressure | 0.6–1 MPa |

| Power | 5 kW |

| Voltage | Three-phase AC 220V, 50/60 Hz |

| Operators needed | 1 person |

| PLC brand | Keyence |

| Touch panel (HMI) | Flexem |

| Optical fiber system | Panasonic |

| Pneumatic components | AirTAC (pneumatics); SMC (air cylinders) |

| Frequency converter | Mitsubishi |

| Solenoid valve | Niscon |

| Category | Machinery & Production Lines |

| Tags | Infusion Sets |

Ready to Place Your Order?

Get a customized quote for your business needs. Our team is ready to assist you with bulk orders, technical specifications, and delivery options.

المراجعات

لا توجد مراجعات بعد.