Machinery & Production Lines

Machinery & Production Lines

PVC Medical Tube Extrusion Line 2–12 mm with X-Ray Line – Radiopaque Medical Tubing Line

Overview

The Φ45 mm Medical Tube with Blue X-Ray Line Extrusion Line is engineered for the production of soft medical-grade PVC tubing

with outer diameters from 2 to 12 mm, incorporating a blue radiopaque stripe for X-ray visibility.

Radiopaque lines are widely used in medical drainage and infusion tubing so that clinicians can track tube position under X-ray and fluoroscopy.

Typical Applications

• Wound drainage tubes with X-ray line.

• Suction and irrigation tubing.

• Respiratory and oxygen tubing.

• General-purpose medical device tubing where X-ray traceability is required.

Line Configuration

1) Φ45 mm Single-Screw Main Extruder

• Screw diameter: 45 mm; L/D = 25:1.

• Special high-precision, mirror-polished screw design for medical PVC.

• Screw and barrel material: 38CrMoAlA nitriding alloy steel.

- Screw nitriding hardness ≥ 950 HV; depth 0.4–0.6 mm; brittleness grade 2.

- Barrel nitriding hardness ≥ 1000 HV; depth 0.6–0.7 mm; water-cooled feed zone.

• Drive motor: 11 kW with frequency inverter control.

• 4 barrel heating zones with band heaters and thermocouples.

• 4 centrifugal cooling fans for stable temperature control.

• Heavy-duty hard-tooth gearbox for high torque and stable plasticizing.

2) Φ25 mm Single-Screw Co-Extruder

• Screw diameter: 25 mm; L/D = 25:1.

• 38CrMoAlA nitrided screw and barrel for long life.

• Drive motor: 2.2 kW with inverter control.

• 3 heating zones and 2 cooling fans.

• Used to extrude the blue radiopaque X-ray stripe.

3) Co-Extrusion Die Head

• Material: S136 mirror-finish tool steel.

• Short flow channel with no dead corners to reduce burn marks and black spots.

• Tube size range: 2–12 mm OD.

• Diameter tolerance at die: approx. ±0.05 mm before final sizing.

4) Vacuum Calibration Stainless-Steel Water Cooling Trough (3 m)

• Length: 3 m; tank material: 2.0 mm stainless steel.

• Center height: 1000 ± 50 mm.

• Three-dimensional manual adjustment (X/Y/Z) with hand wheels.

• Square-steel support frame.

• Independent water circulation system.

• Vacuum pump: 2.2 kW; water pump: 0.37 kW.

5) Stainless-Steel Water Cooling Trough (3 m)

• Length: 3 m; 2.0 mm stainless steel tank.

• Center height: 1000 ± 50 mm.

• 3D manual adjustment and steel support frame.

• Water circulation with 0.37 kW pump.

• Nylon sealed water blower to remove surface water without splashing.

6) Online Diameter Measurement System

• Brand: Laser Online, model: LST-25.

• Measuring range: 0.1–25 mm.

• Accuracy: ±0.002 mm.

• Resolution: 0.001 mm for precise diameter control during production.

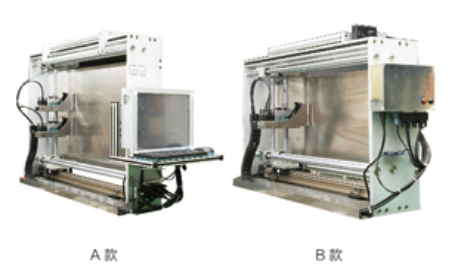

7) Siemens Servo Haul-off & Cutting Unit

• PU Poly-V belts, effective conveying length: 500 mm.

• Aluminum haul-off rollers with up/down linear guide rails.

• Bevel gear transmission.

• Haul-off servo motor: 1 kW with Siemens servo drive.

• Haul-off speed: 0–60 m/min.

• Cutting servo motor: 1 kW with Siemens servo control.

• Siemens PLC module and HMI touch panel with alarm and parameter settings.

8) Conveyor and Collection Unit

• Conveyor belt length: 2 m; effective collection length: 1 m.

• Pneumatic control system.

• Stainless-steel collection tray for finished tubes.

9) Electrical & Control System

• Siemens PLC and touch screen HMI.

• Delta inverters and Yangming solid-state relays.

• Branded electrical components neatly wired and labeled for easy maintenance.

10) Spare Parts Kit

• Barrel heaters ×2.

• Die head heaters ×2.

• Haul-off belt ×1.

• Thermocouples ×4.

• Scraping pot ×1.

• Selector switches ×2.

• Push buttons ×2.

• Screwdriver and hex key set.

• One additional solid state relay.

Key Advantages

• Radiopaque X-ray line co-extruded with the tube for reliable X-ray visibility.

• High dimensional precision via S136 die, vacuum sizing and in-line laser diameter gauge (±0.002 mm).

• Robust stainless-steel cooling and collection equipment suitable for clean medical production environments.

• Reliable electrical system with Siemens PLC & HMI, Siemens servo drives and Delta inverters.

• Balanced output of around 20–30 kg/h with installed power about 40 kW – ideal for specialized medical tubing production.

Why Alrowad Pico

• Engineering support for line layout, process parameters and radiopaque compound selection.

• Ability to integrate this extrusion line into a complete medical disposables factory (drainage bags, tubing, urine bags, etc.).

• Local technical team for installation, commissioning and after-sales service.

Technical Specifications

| SKU | MEDICAL-PVC-TUBE-EXTRUSION-XRAY |

|---|---|

| Tube size (OD) | 2–12 mm |

| Material | Medical-grade PVC with radiopaque X-ray line |

| Line speed | 0–60 m/min |

| Category | Machinery & Production Lines |

| Tags | Extrusion |

Ready to Place Your Order?

Get a customized quote for your business needs. Our team is ready to assist you with bulk orders, technical specifications, and delivery options.

المراجعات

لا توجد مراجعات بعد.