Machinery & Production Lines

Machinery & Production Lines

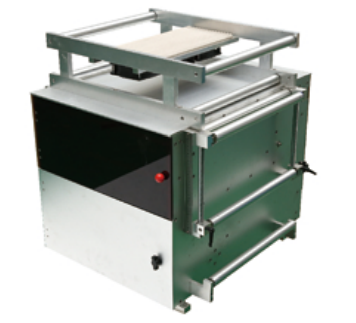

Infusion Set Packing Machine – Shunjin Medical

Infusion Set Packing Machine

The Infusion Set Packing Machine from Shunjin Medical is a fully automatic solution dedicated to packing complete IV infusion sets at high speed while maintaining stable performance and consistent packaging quality. It is designed for medical device factories that need to increase throughput, reduce labor cost and improve packaging hygiene for disposable infusion products supplied to hospitals, clinics and medical distributors.

The machine is engineered for a stable packing capacity of up to 3,500 sets per hour, making it suitable for medium to large scale production environments. By automating the packing stage, manufacturers can streamline the final steps of the infusion set line after assembly and inspection, reduce manual placement work and improve repeatability across batches. Automated packing also supports improved cleanliness by reducing direct hand contact with finished medical products.

The equipment is built with a heavy-duty structure (about 4,000 kg) to enhance stability during continuous operation. The footprint of 7500×5500×2500 mm provides a dedicated working area and supports integration into packaging zones within medical manufacturing layouts. Utility requirements match typical industrial installations: three-phase AC 380V, 50/60 Hz power supply and compressed air within standard factory ranges.

In terms of automation architecture, the machine combines a central PLC control system with a touch-screen HMI for intuitive operation, quick parameter adjustments and alarm handling. Precision motion is supported through servo systems and frequency converters, enabling accurate feeding and packing sequences. The pneumatic subsystem uses industrial cylinders and solenoid valves for smooth, repeatable actuation, while sensors help verify product presence and positioning during the packing cycle.

Typical applications: IV infusion set packing after assembly lines, medical disposables packaging departments, and factories upgrading from manual packing to automated packaging to support capacity expansion, quality consistency and hygiene goals.

- Up to 3,500 sets/h packing capacity

- Dedicated for complete IV infusion set packing

- PLC control with touch-screen HMI

- Industrial-grade servo motion and pneumatic systems

Technical Specifications

| SKU | SJ-INFUSION-SET-PACK-001 |

|---|---|

| Packing speed | Up to 3, 500 pcs/h |

| Packed parts | Infusion set |

| Machine weight | 4000 kg |

| Equipment size (L×W×H) | 7500 × 5500 × 2500 mm |

| Air consumption | 0.07 m³/h |

| Air pressure | 0.6–1 MPa |

| Power | 8 kW |

| Voltage | Three-phase AC 380V, 50/60 Hz |

| Operators needed | 2–3 persons |

| PLC brand | Keyence |

| Touch panel (HMI) | Kinco |

| Servo system | Mitsubishi |

| Frequency converter | Mitsubishi |

| Pneumatic components | AirTAC |

| Optical fiber system | Panasonic |

| Magnetic sensor | ALIF |

| Relay | Dinkle |

| Category | Machinery & Production Lines |

| Tags | Infusion Sets |

Ready to Place Your Order?

Get a customized quote for your business needs. Our team is ready to assist you with bulk orders, technical specifications, and delivery options.

Reviews

There are no reviews yet.