Machinery & Production Lines

Machinery & Production Lines

Roller Clamp Assembly Machine for Infusion Sets – Shunjin Medical

Roller Clamp Assembly Machine for IV Infusion Sets

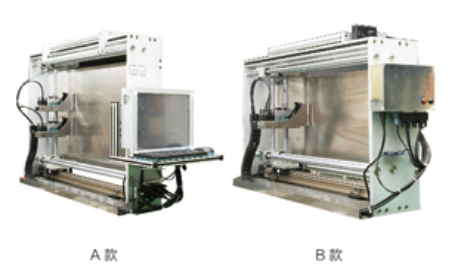

The Roller Clamp Assembly Machine from Shunjin Medical is a dedicated automatic production solution for assembling roller clamps used in IV infusion sets. Roller clamps are standard flow-control components in gravity-driven infusion systems; they allow clinicians to open, restrict or stop fluid flow by rolling a wheel within a clamp housing. Consistent clamp geometry and smooth roller movement are essential for stable flow regulation and for compatibility with common infusion tubing sizes.

This machine automates the assembly of the two core parts: the roller and the clamp housing. The workflow is designed as a continuous industrial sequence: loading the roller, loading the clamp housing, assembling both parts automatically, and discharging finished roller clamps. By removing manual assembly variability, manufacturers can improve output consistency and reduce labor cost on high-volume lines producing disposable IV sets.

Production performance is rated at approximately 6,500–7,000 pieces per hour. The compact frame (1500×1000×1500 mm) and weight of about 300 kg make it suitable for clean-room or controlled-environment layouts where space utilization matters. Pneumatic utilities are economical, with air consumption around 0.03 m³/h at 0.4 MPa operating pressure, which helps keep operating costs aligned with standard factory compressed-air systems.

The control architecture combines an Omron PLC with a Kinco touch panel, providing an intuitive operator interface for monitoring output, counts and alarms. Part detection and positioning are supported by optical fiber sensing, and key pneumatic components and cylinders are specified from widely used brands to support long service life and maintenance planning.

Typical applications: roller clamp production for IV administration sets, infusion set assembly lines, and medical disposables factories that require stable, high-throughput clamp output prior to tubing assembly, drip chamber integration and final packaging.

- 6,500–7,000 pcs/h output

- Assembles roller + clamp housing

- Compact footprint for clean manufacturing layouts

- Omron PLC + touch-screen operation

Technical Specifications

| SKU | SJ-ROLLER-CLAMP-ASM-001 |

|---|---|

| Assembly speed | 6, 500–7, 000 pcs/h |

| Assembly parts | Roller; Clamp housing |

| Machine weight | 300 kg |

| Dimension (L×W×H) | 1500 × 1000 × 1500 mm |

| Air consumption | 0.03 m³/h |

| Air pressure | 0.4 MPa |

| Power | 0.8 kW |

| Voltage | Single phase AC 220V, 50/60 Hz |

| Operators needed | 1 person |

| PLC brand | Omron |

| Touch panel (HMI) | Kinco |

| Optical fiber system | Panasonic |

| Pneumatic components | AirTAC (pneumatics); SMC (cylinders) |

| Solenoid valve | Niscon |

| Magnetic sensor | ALIF |

| Category | Machinery & Production Lines |

| Tags | Infusion Sets |

Ready to Place Your Order?

Get a customized quote for your business needs. Our team is ready to assist you with bulk orders, technical specifications, and delivery options.

Reviews

There are no reviews yet.