Machinery & Production Lines

Machinery & Production Lines

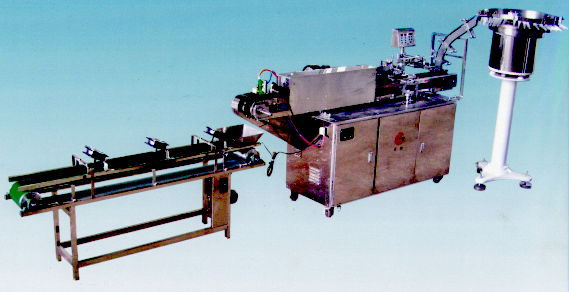

Automatic Syringe Silk Screen Printing Machine – Graduation Printer 1–50 ml

Overview

This syringe automatic silk screen printer is designed for round-surface printing on disposable syringe barrels

and similar cylindrical products. It provides clear, durable graduation marks and logos with high efficiency,

low power consumption and easy mechanical adjustments.

Use and Printing Range

• Main application: printing graduations and markings on single-use syringe barrels.

• Syringe sizes: 1–50 ml (typical range from the manual).

• Shape of printed object: cylindrical, round diameter approx. 8–40 mm, length approx. 50–130 mm.

• Printing position: round straight surface of the syringe barrel.

Key Features (from the user manual)

• High working efficiency with adjustable printing speed from 10–90 pcs/min.

• 0.75 kW timing motor as main drive, helping reduce energy consumption and running cost.

• Low operating cost, simple mechanical adjustment and wide application range.

• Automatic feeding via vibrating feeder and chain indexing structure for stable positioning.

• Round-surface silk screen printing with scraper and mesh frame designed for syringe barrels.

Structure & Systems

• Main machine with chain conveyor and roller supports for syringe barrels.

• Automatic vibrating feeder and rail to orient and feed syringes into the printing station.

• Silk screen frame, scraper and ink system with adjustable pressure and registration.

• Adjustment mechanisms for slider, chain side plates and idler wheels to adapt to different syringe sizes.

• Electrical system based on three-phase four-wire power supply, with speed controller and control panel.

Typical Benefits

• Clear and repeatable graduation printing on syringe barrels, improving product appearance and readability.

• Flexible speed control for matching upstream injection moulding or assembly lines.

• Lower energy and maintenance cost compared with manual or semi-automatic printing solutions.

• Suitable for integration into complete disposable syringe production lines from injection to printing and packing.

Technical Specifications

| SKU | ZR-SYRINGE-SILK-PRINTER |

|---|---|

| Printing speed | Adjustable 10–90 pcs/min (timing motor) |

| Syringe size range | 1–50 ml, diameter approx. 8–40 mm, length approx. 50–130 mm |

| Motor power | 0.75 kW timing motor (three-phase, four-wire system) |

| Category | Machinery & Production Lines |

| Tags | Syringes |

Ready to Place Your Order?

Get a customized quote for your business needs. Our team is ready to assist you with bulk orders, technical specifications, and delivery options.

Reviews

There are no reviews yet.